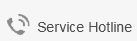

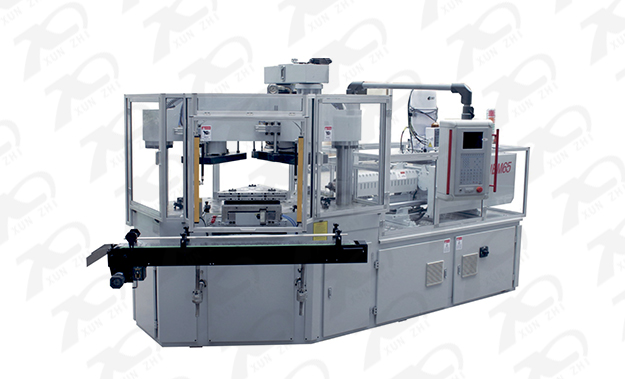

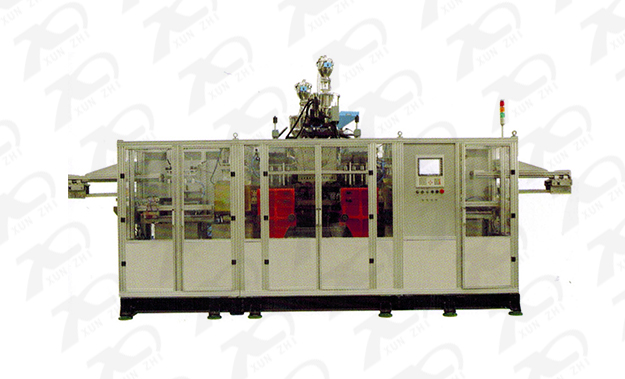

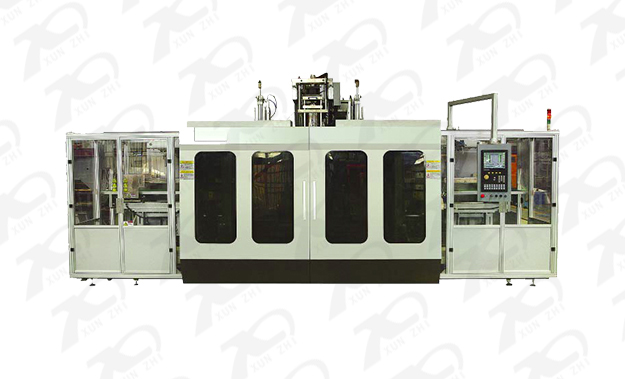

Hand insert embryo full automatic bottle ...

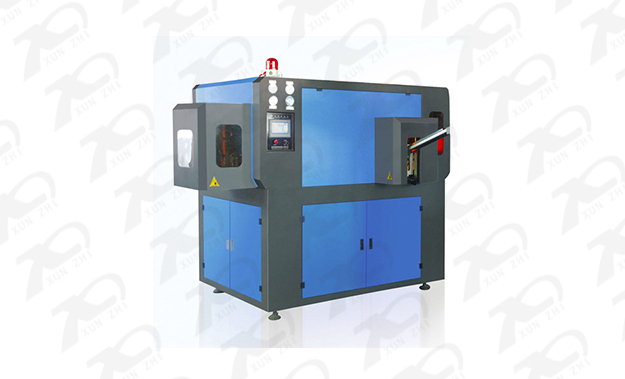

1) high speed and efficiency: the new product model is equivalent to the original two to three sets of semi automatic machine efficiency.

2). Labor: new models of single operation, saving 2 to 3 people in the labor force.

3). The main performance and the slide type integration. Maintenance is simple.

4. Imported touch screen man-machine interface computer, with the performance of fine, fast, strong stability.

5) selection of Germany, Japan, Taiwan imported pneumatic components, to ensure that the high-speed operation of zero failure rate.

6). Gas blowing and action design is divided into two parts, in order to meet the needs of the different pressure of the blowing bottle, action, achieve high pressure blowing products, the double elbow, the main connecting rod hinge clamping force is strong, with high pressure bottle blowing machine when the clamping pressure function, steady and reliable action.

7). Mold moving parts with high-speed rail line, with high wear resistance, high speed mold light and no vibration etc...

| Name | Unit | JG-1C5L | JG-2C2L | JG-1C120MM | JG-2C120MM | JG-1C20L |

| Theoretical yield | pcs/hr | 750 | 2500 | 800 | 1500 | 180 |

| Bottle maximum capacity | L | 5 | 2 | 8 | 8 | 20 |

| The maximum diameter of the bottle | mm | 50 | 45 | 120 | 120 | 100 |

| Bottle Max diameter | mm | 175 | 100 | 200 | 200 | 300 |

| Maximum height of bottle | mm | 350 | 340 | 350 | 350 | 450 |

| Cavity number | cavity | 1 | 2 | 1 | 2 | 1 |

| Installed capacity | kw | 28 | 28 | 42 | ||

| Rated power of heating | kw | 27 | 27 | 40 | ||

| Actual heating power | kw | 15 | 15 | 28 | ||

| Machine size | mm | 1900*1400*2000 | 1900*1600*2200 | 3400*2100*2200 | ||

| Machine weight | kg | 1800 | 1800 | 2800 |