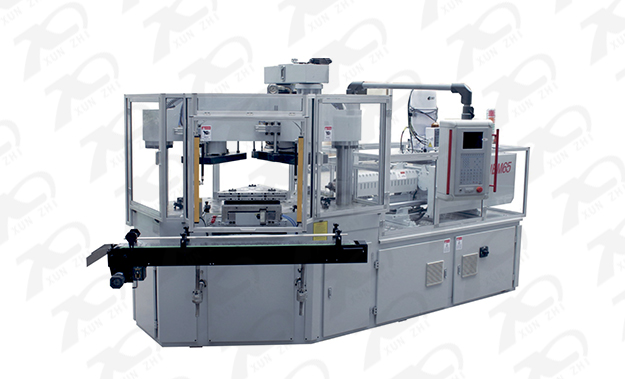

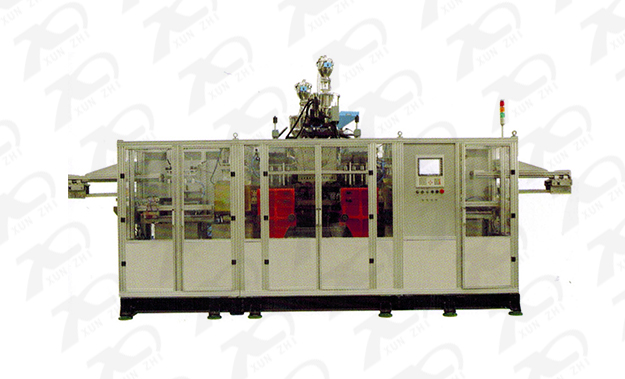

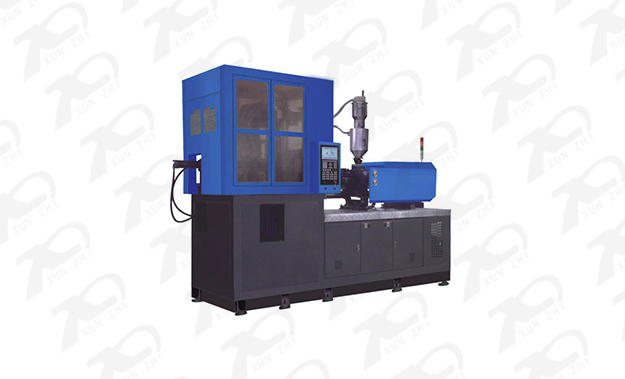

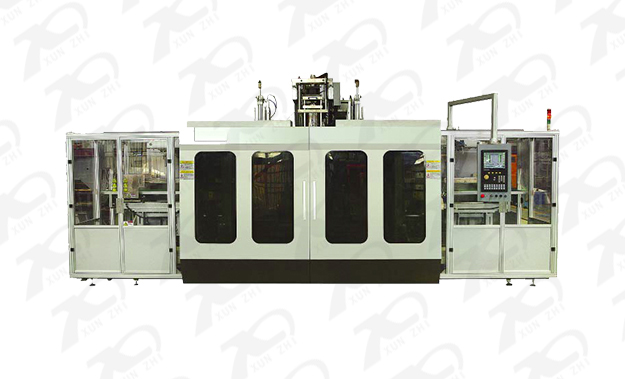

TDB-25APC blow molding machine for pure water bucket and lamp shade

- Product Features

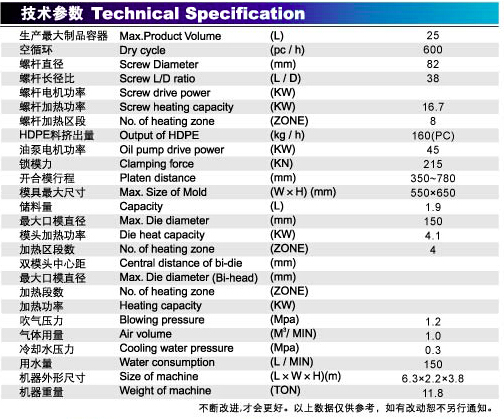

- Parameters

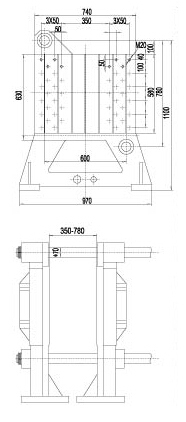

- Structure Diagram

- Applicable Bottle Type

An electrical system: Japanese MITSUBISHI PLC computer with machine interface (Chinese or English) control, color touch screen. All the functions of process setting, change, search, monitoring, fault diagnosis and so on are realized on the touch screen.

Two, hydraulic system: proportional pressure control, equipped with imported famous brand of hydraulic components, stable and reliable.

Three, blank control: 30, the Japanese original MOOG company production wall thickness control system.

Four, the plastic system: high efficient mixing exhaust screw, screw by the hydraulic motor drive to achieve the stepless speed regulation. Resistance ruler to control radiation, high precision.

Five, the open die: die, clamping mechanism adopts the sliding ball linear guide, micron level accuracy. High precision mold, full stroke positioning light, energy saving, and strong bearing, no deformation. Patent products: two rod, single cylinder bidirectional synchronous clamping center locking mechanism, good product stability.

Six, die head: PC special die head. Vertical FIFO structure, materials with special steel by ammoniation and.

Seven, blowing system: double filtration. Pressure regulating air system to ensure that the gas path is clean and pressure is stable, the configuration of SMC maintenance free electromagnetic valve is more durable.