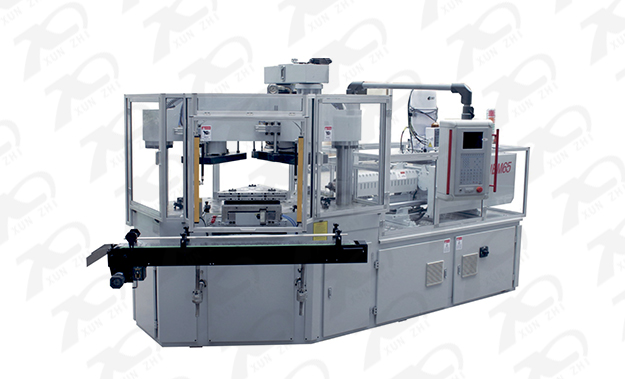

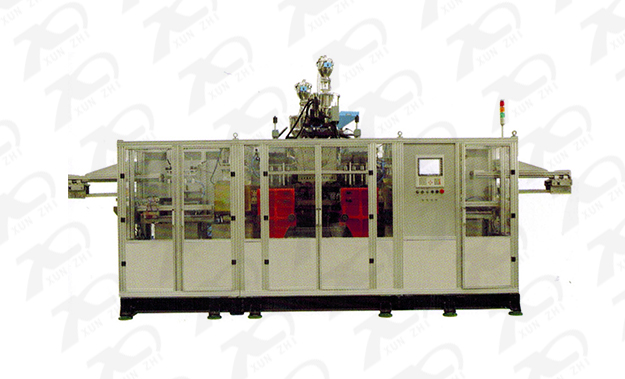

TDB-25A Full automatic blow molding hollow forming machine

- Product Features

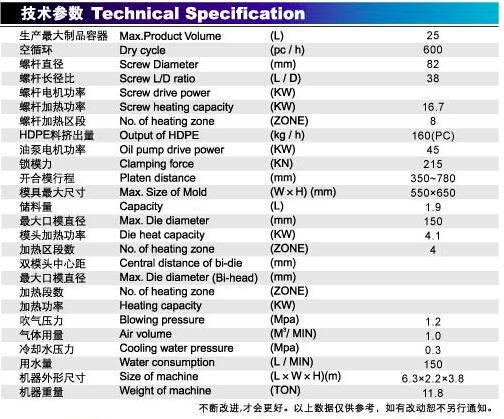

- Parameters

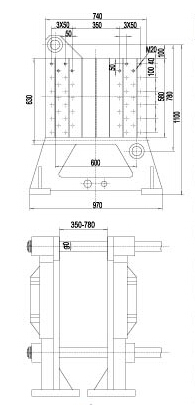

- Structure Diagram

- Applicable Bottle Type

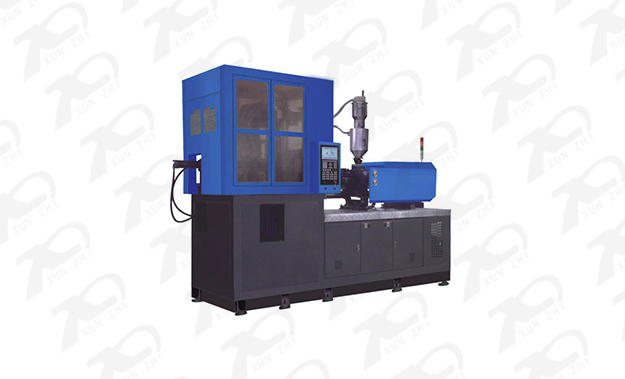

An electrical system: Japanese MITSUBISHI PLC computer with machine interface (Chinese or English) control, color touch screen. All the functions of process setting, change, search, monitoring, fault diagnosis and so on are realized on the touch screen.

Two, hydraulic system: proportional pressure control, equipped with imported famous brand of hydraulic components, stable and reliable.

Three, the plastic system: high efficient mixing screw, to ensure full and uniform plastic plastic.

Four, speed control system: frequency control + alloy steel Hardened reducer, stable speed, low noise, durable.

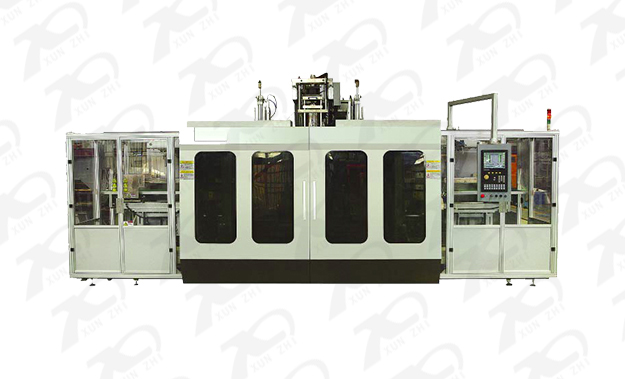

Five, the open die: die, clamping mechanism adopts the sliding ball linear guide, micron level accuracy. High precision mold, full stroke positioning light, energy saving, and strong bearing, no deformation. Patent products: two rod, single cylinder bidirectional synchronous clamping center locking mechanism, good product stability.

Six, shot material: independent single (big) cylinder shot, to ensure that the shot material concentric degree, absolutely avoid the phenomenon of double cylinder is not synchronized. With the unique technology of 10 injection pressure wall thickness control function, reduce blank should be hung on the width and bring differences, effectively improve the product with high wall thickness uniformity.

Seven, die head: all use 38CrMoAlA, 42CrMoV, 35CrMo and other fine materials, by precision machining and heat treatment.

Eight, the replacement of the mold die on the same effort: Taiwan can also lift and move backward, forward (hydraulic control), easy to install all kinds of mold space, lifting die, die and is convenient for production at die spacing, more than expected at least.

Nine, low energy consumption: production rate of about 70%, energy consumption for the H 6KW than the original model of energy saving 26.6KW H.