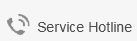

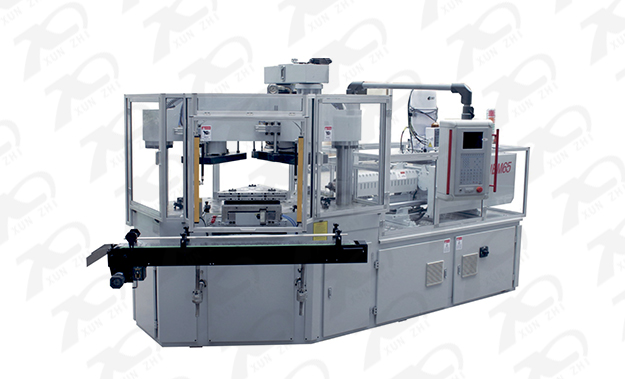

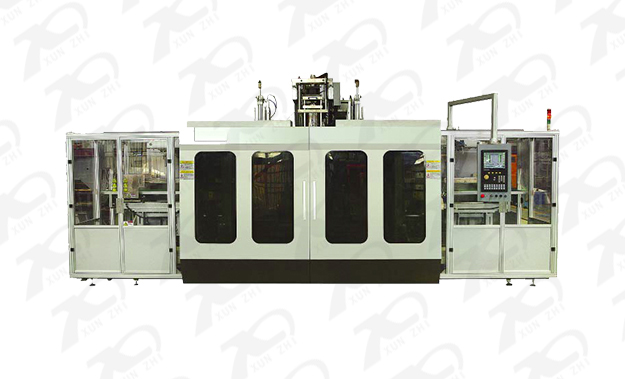

Full automatic hot filling bottle ...

No matter what you want to pack, liquid light can provide you with the best technology. Including: bottle design, mold production, tube blank and bottle cap injection molding, PET full automatic bottle blowing machine, liquid filling.

In the process of manufacturing, processing, debugging, use the most professional technology giant light, for you to improve productivity, quality control, cost reduction, to ensure that all machines can run well, let you win the market benefit in the short term.

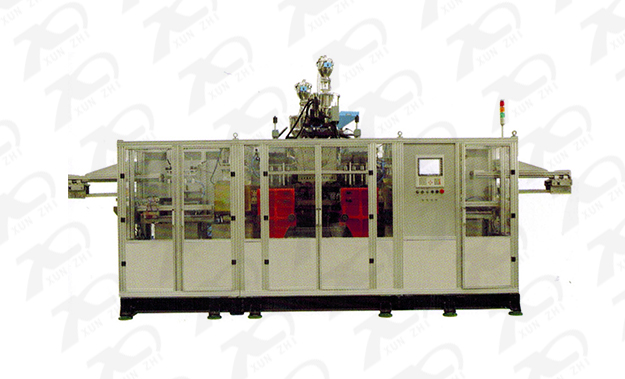

Naming rules for bottle blowing machines:

| Name | Unit | JG-2C2LR\F(hot fill) | JG-4C2LR\F(hot fill) | JG-6C2LR\F |

| Theoretical yield | pcs/hr | 1300 | 2500 | 4500 |

| Bottle maximum capacity | L | 1.5 | 1.5 | 1.5 |

| The maximum diameter of the bottle | mm | 45 | 45 | 45 |

| Bottle Max diameter | mm | 90 | 90 | 90 |

| Maximum height of bottle | mm | 320 | 320 | 320 |

| Cavity number | cavity | 2 | 4 | 6 |

| Installed capacity | kw | 74 | ||

| Rated power of heating | kw | 72 | ||

| Actual heating power | kw | 32 | ||

| Machine size | mm | 4600*2000*2200 | ||

| Machine weight | kg | 4200 |