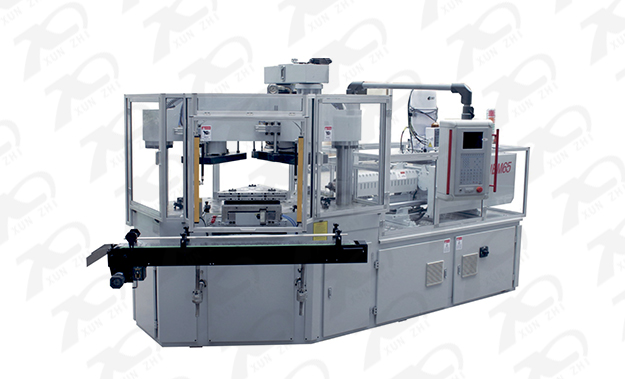

TDB-2000LLarge scale hollow forming machine

- Product Features

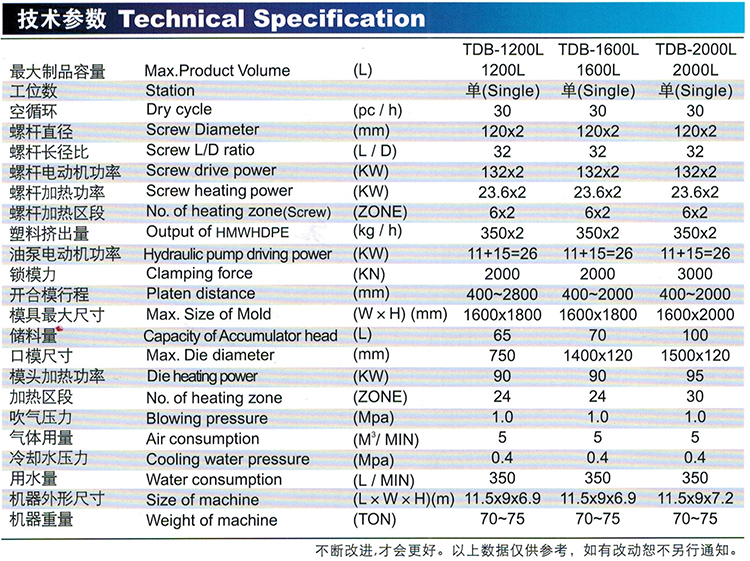

- Parameters

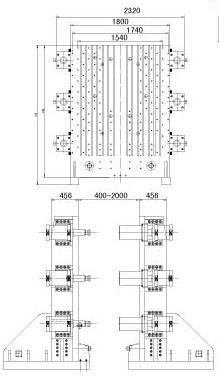

- Structure Diagram

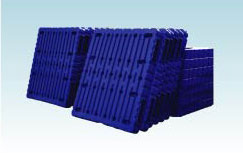

- Applicable Bottle Type

An electrical control system: MITSUBISHI PLC computer man-machine interface control, in English cantilever control panel, a temperature control system with independent control of temperature control instrument, reduce maintenance costs. All the functions of process setting, change, search, monitoring, fault diagnosis and so on are realized on the touch screen. Electric control cabinet standard, the device stable running environment, prolong the service life of the equipment.

Two, hydraulic system: proportional pressure control, equipped with imported brand-name hydraulic valves and pumps, stable and reliable. 100 point electro hydraulic servo control system is adopted, and the power storage device is adopted in the electro-hydraulic servo system. This hydraulic system is very energy saving.

Three, the plastic system: the use of two 1KV high efficient mixing screw, to ensure that the plastic plastic full, uniform, extrusion volume reached 700kg/h.

Four, speed control system of DC speed control system + alloy steel Hardened reducer, starting with good rigidity, large driving torque, stable speed, energy saving, low noise, durable.

Five, open mold, mold moving system with two pin lock mechanism at the bottom of the template template, using linear guide by clamping oil cylinder to realize the clamping, clamping force and balance, can realize the micro mold, so as to ensure locking when the clamping force is enough, when the smooth mold mold. This pin lock mechanism has applied for a patent for invention.

Six, 2000L manipulator: clamping plate using a double cylinder independent drive, the clamping plate on the installation of circulating cooling water. The manipulator has a large clamping force, and can clamp the heavier products.

Seven, the nose using the storage type flat head, suitable for the production of flat plate type blow molding products, the storage cylinder using an external way to facilitate the processing and processing of the nose and processing of products. The flow channel design is streamlined to minimize the impact on the melt. This nose has applied for a patent for invention.

Eight, under the blowing device and pre clamping device: the lower part of the clamping unit is installed under the blowing device, can realize the pre blow molding blow. The clamping plate of the pre clamping device adopts a double cylinder independent drive, and a circulating cooling water is arranged on the clamping plate.

Nine, the replacement of mold saving: the mold closing system from around the device, the lifting of the mold is very convenient.

Ten, low energy consumption: the production of 1400*1200*150mm hollow tray, the average 20KW.h/ block tray, compared with foreign equipment, but also energy saving.