Description

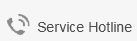

Bottle design

The international advanced 2D&3D software design of the appearance of the bottle, to meet the needs of today's market for all kinds of plastic products design. The experience of the design team will be able to get rich for your bottle type design concept into reality.

Quality materials

45 carbon steel as a standard material for blowing mould, because it is easy to process after forging. At the same time, we also provide S136 models of steel. S136 for a stainless steel, has a very high hardness (for HRC30). The mould cavity which is made of the steel can not be processed by the gold plating process, and the service life of the mould is longer. For the full automatic bottle blowing machine, the material can provide better cooling effect and light weight.

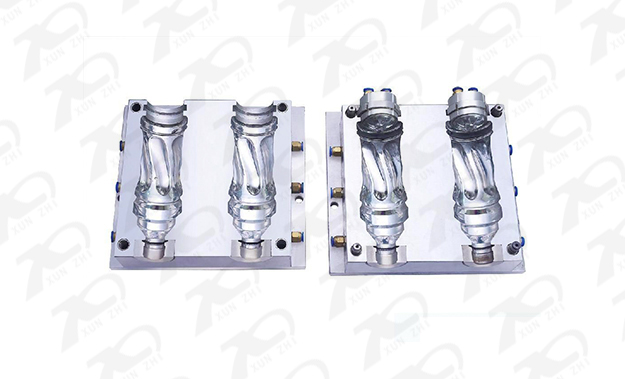

Processing equipment

For different types of bottles, caused by the news processing departments with different equipment, such as the 3 axis machining center processing equipment, precision machining center and other professional to ensure the final blow mold capacity required to dispatch by blowing mould in series with the inter industry competitiveness be enhanced.

Appearance processing

After finishing the final blow bottle test, it is usually in the surface layer of hard chromium coating to extend the service life of the mold.

Quality Control

Prior to the design of the mold, the design team of the information to optimize the design of the bottle. In the process of manufacturing, all digital processing equipment and technology to ensure the quality of the final mold. After completion, we carried out a number of test modules, to test the true capacity of the bottle produced and the final bottle type. If there is a problem, we will make the necessary adjustments to the mold to meet the customer's requirements.

1 we support to help customers develop. If you need to be able to document or improve design.

2 according to the information given, the mold quotation will be completed in 1 days.

3 quality, price, material, delivery time, payment items, etc..

4 mold and product 3D/3D drawing design requires 3-5 days.

5 modeling according to customer's requirements. Before making the mold, we will send the mold design to the customer first. Customers agree that the mold will usually be completed within 30-65 days.

6 when the mold is complete, we will test the mold to check whether it can meet the needs of consumers. We will send the sample to confirm to the customer.

7 if the first sample out of the customer is not satisfied, we will change until the customer satisfaction.