Description

Plastic hollow molding refers to the use of compressed air blowing hollow containers and vacuum suction into shell containers. Blow molding hollow containers are mainly used in the manufacture of thin-walled plastic bottles, barrels and toys plastic parts. Blister hollow containers are mainly used in the manufacture of thin-walled plastic packaging supplies, cups, bowls and other disposable containers. Hollow blow molding is the plastic state of the plastic parison in the mold, the compressed air into the parison to blow up so that the shape of the product after inflation and the shape of the same mold cavity, cooling stereotypes to get the desired product . According to the different forming methods, can be divided into extrusion blow molding, injection blow molding, injection stretch blow molding, multi-layer blow molding, sheet blow molding and other forms.

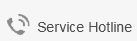

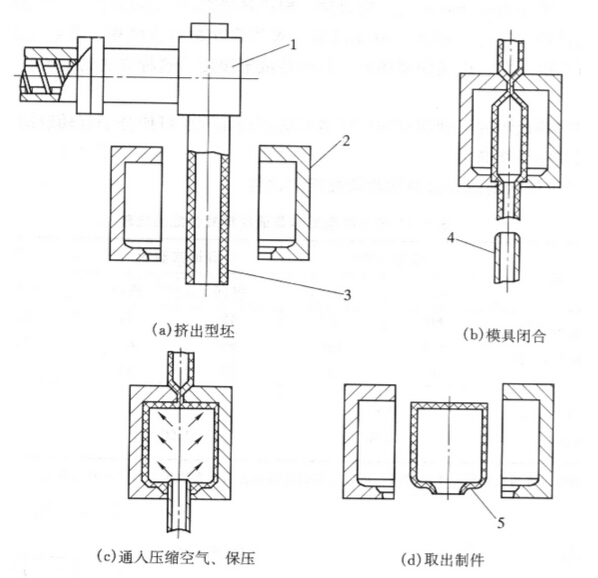

① extrusion blow molding

Extrusion blow molding is the primary method of forming hollow plastic parts. First extruding the tubular parison in the extruder; cutting a section of the tube into the mold while it is hot, closing the upper and lower ends of the parison while closing the open mold; and introducing the compressed air into the cavity to expand Attached to the cavity wall and forming, and then pressure; the final cooling by stereotypes, can remove the compressed air and mold removal of plastic parts. Extrusion blow molding die structure is simple, less investment, easy operation, suitable for a variety of plastic hollow blow molding. Drawback is not easy to uniform wall thickness, plastic parts to be removed after processing flash.

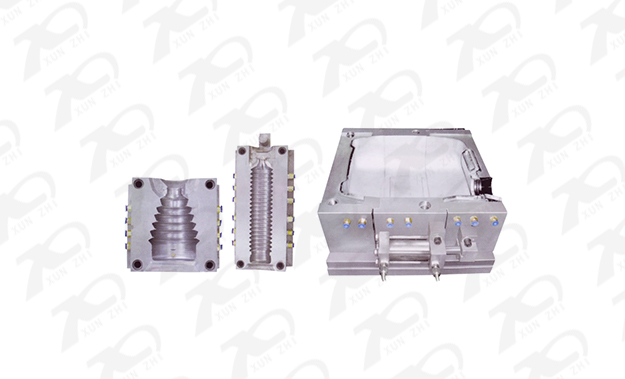

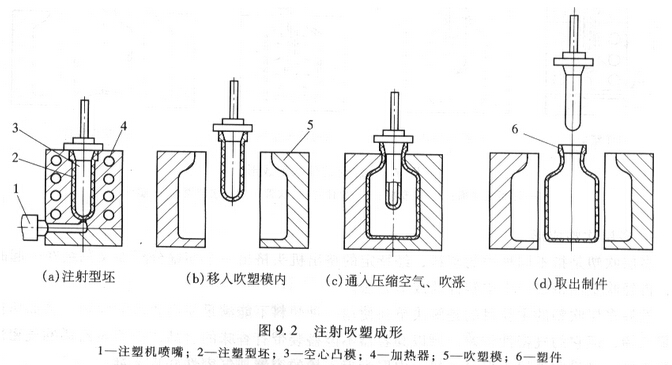

② Injection blow molding Injection blow molding is the use of injection molding machine in the injection mold in the parison, and then move the hot parison into the hollow blow mold for hollow blow molding. Injecting a molten plastic into a parison; injecting the core into the blow mold together with the parison, the core being hollow and having a hole in the wall; and introducing compressed air from the pipe of the mandrel, The parison blows and affixed to the mold cavity wall; pressure, cooling after the release of compressed air stereotypes, and mold removal of plastic parts. After injection molding plastic parts of the wall thickness uniform, no flash, no post-processing, by the dry injection of parison with bottom, so the bottom is not spell and seam, high strength, high production efficiency, but the equipment and mold expensive , Used for small-scale plastic parts of mass production.

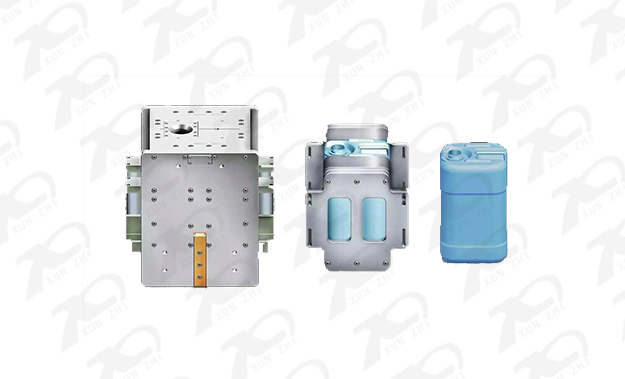

③ injection stretch blow molding

Injection stretch blow molding and injection blow molding compared to increase the extension of this process. First, a hollow bottomed parison is injected; the parison is moved to a stretching and blow molding station, stretched; blow-molded, held in pressure; and cooled to remove the molding. There is another injection stretch blow molding method, that is, cold billet forming method, parison injection and plastic parts of the stretch blow molding were carried out in different equipment, parison injection finished, then moved to blow Blow molding machine, this time the parison has been distributed some heat, the need for secondary heating to ensure the parison stretch blow molding temperature, the main feature of this method is relatively simple equipment structure.